About Us

Chain Fan Electrical Industry Corp.

Established in Taiwan in 1983, Chain Fan Electrical Industry Corp. is a brushless DC motor manufacturer specializing in the production of electric motors for various applications, including electric fans, industrial fans, exhaust fans, and ceiling fans. With nearly four decades of expertise, we have continuously set benchmarks for innovation, quality, and customer satisfaction. We also provide fan OEM/ODM services to help businesses customize and scale their fan products globally.

Company Milestones

- 1983 – Established in Taichung County, Taiwan

- 1987 – Registered CHAIN FAN ELECTRICAL INDUSTRY CORP.

- 1994 – Invested and set up WELL TIME INDUSTRIAL CO., LTD. at Tan Thuan Export Processing Zone in Ho Chi Minh City, Vietnam.

- 2002 – Established the second factory WELLY INDUSTRIAL CO., LTD. at Nhon Trach 2 Industrial Zone, Dong Nai Province, Vietnam.

- 2019 – Reorganization: WELL TIME INDUSTRIAL CO., LTD. merged into WELLY INDUSTRIAL CO., LTD.

Expansion and Global Reach

In 2002, recognizing the growing global demand for motor products, we expanded our operations by founding Welly Industrial CO., Ltd. in Vietnam. This strategic move allowed us to diversify our product range and better cater to international customers. Equipped with a comprehensive production line, Welly enhances our capabilities as a brushless DC motor manufacturer, ensuring increased production volume, consistent product quality, cost efficiency, timely deliveries, and operational safety.

Global Market Distribution

Our products are distributed worldwide, with market coverage as follows:

- North America: 10%

- South America: 15%

- Europe: 30%

- Asia: 35%

- Oceania: 10%

This balanced global presence enables us to serve a wide range of industries and maintain close partnerships with customers across continents.

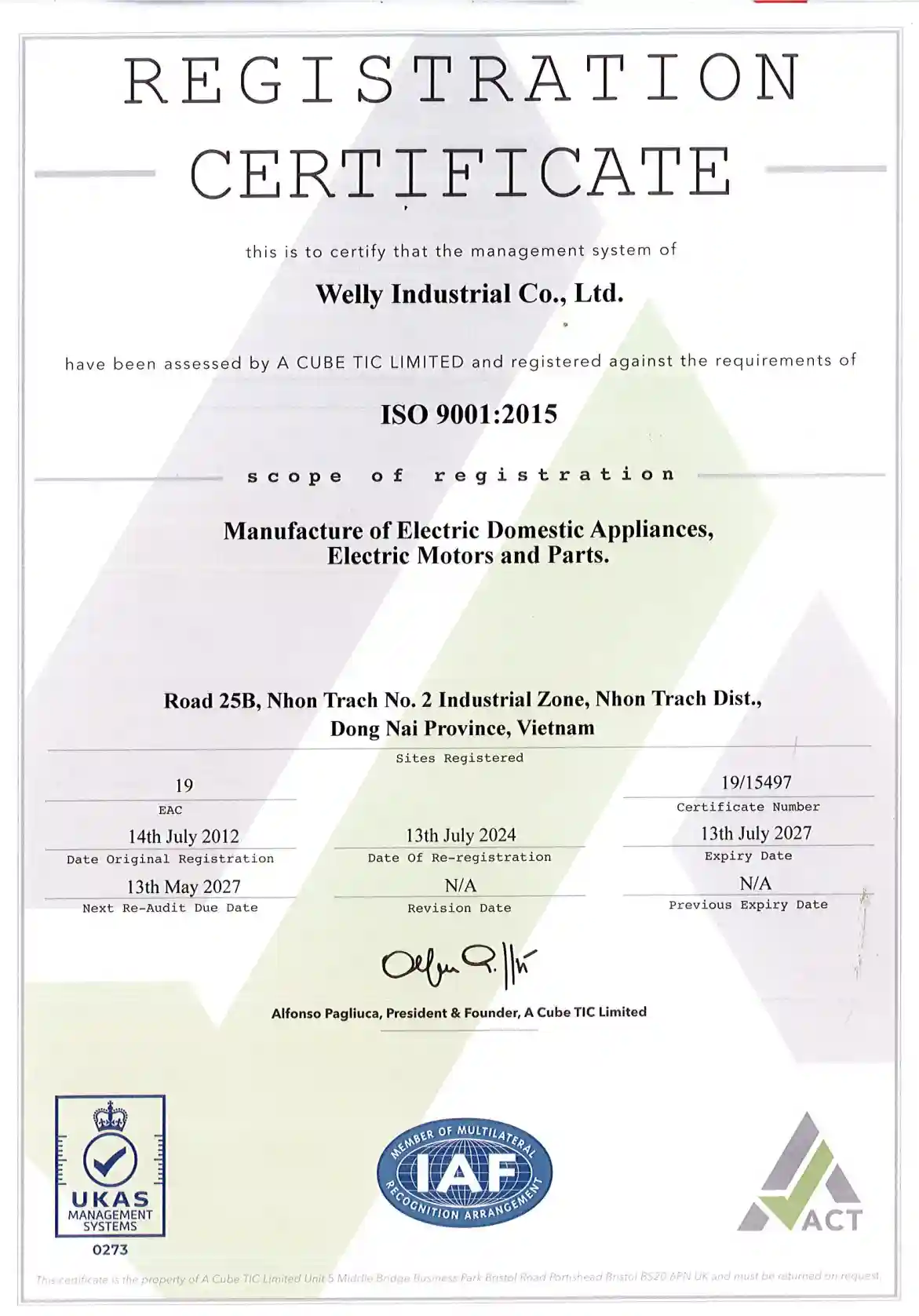

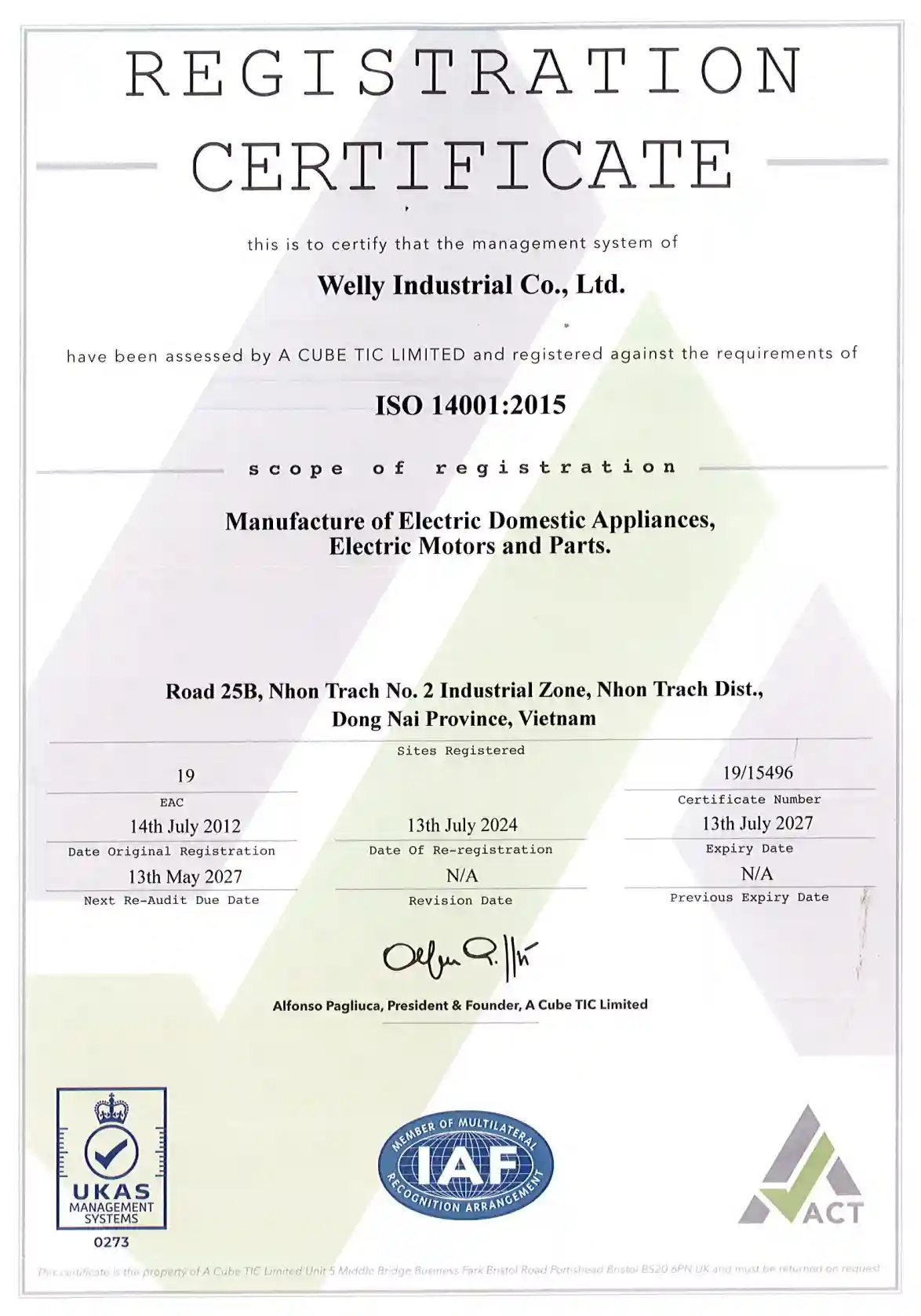

Commitment to Quality and Environmental Standards

We adhere rigorously to global standards, as evidenced by our ISO 9001 and 14001 certifications obtained in 2003 and 2006, respectively. These certifications underscore our commitment, as a brushless DC motor manufacturer, to stringent quality management and environmental practices.

Our Key Manufacturing Equipment for Motor Production

- High-Speed Punching Machine

- We use high-speed punching machines for stators, rotors, and motor covers. They ensure precision, consistent magnetic performance, and high production efficiency.

- Plastic Injection Machine

- Our plastic injection machines produce motor casings, fan blades, and insulation parts with high accuracy and design flexibility.

- Painting Equipment

- We are equipped with painting equipment for guards, pipes, covers, and blades, providing corrosion resistance and uniform, durable finishes.

- Motor Shaft Processing Machine

- Our motor shaft processing machines guarantee precise dimensions and smooth rotation for stable, low-vibration performance.

- Aluminum Die-Casting Machine

- We use aluminum die-casting machines to form strong, lightweight motor housings with excellent heat dissipation and accuracy.

Focus on Innovation and Sustainability

In recent years, we have intensified our focus on research and development, particularly in advancing our BLDC motor series. This initiative reflects our dedication as a brushless DC motor manufacturer to leverage cutting-edge technology and deliver superior, eco-friendly products that meet the evolving needs of our clientele worldwide.

Future Outlook

Looking ahead, we are committed to further advancing our technological capabilities and fan OEM/ODM services to offer more efficient and sustainable solutions. As responsible corporate citizens, we are dedicated to contributing to environmental sustainability by promoting energy conservation and emissions reduction initiatives.

|

|